As we approach 2025, the landscape of manufacturing and construction is poised for significant evolution, particularly in the realm of materials. Among these, Stainless Steel Plates stand out as a versatile and durable choice that continues to gain traction across various industries. With advancements in technology and design, the applications of stainless steel plates are expanding, offering both aesthetic and functional benefits that are hard to overlook.

In this article, we will delve into the top trends shaping the future of stainless steel plates. From innovative manufacturing techniques that enhance strength and durability to eco-friendly practices that promote sustainability, we will explore what to look for in the coming years. As industries increasingly strive for efficiency and adaptability, understanding these trends will be crucial for stakeholders keen on leveraging the capabilities of stainless steel plates in their projects. Whether in architecture, transportation, or consumer products, staying informed about these developments will ensure that you remain at the forefront of this ever-evolving field.

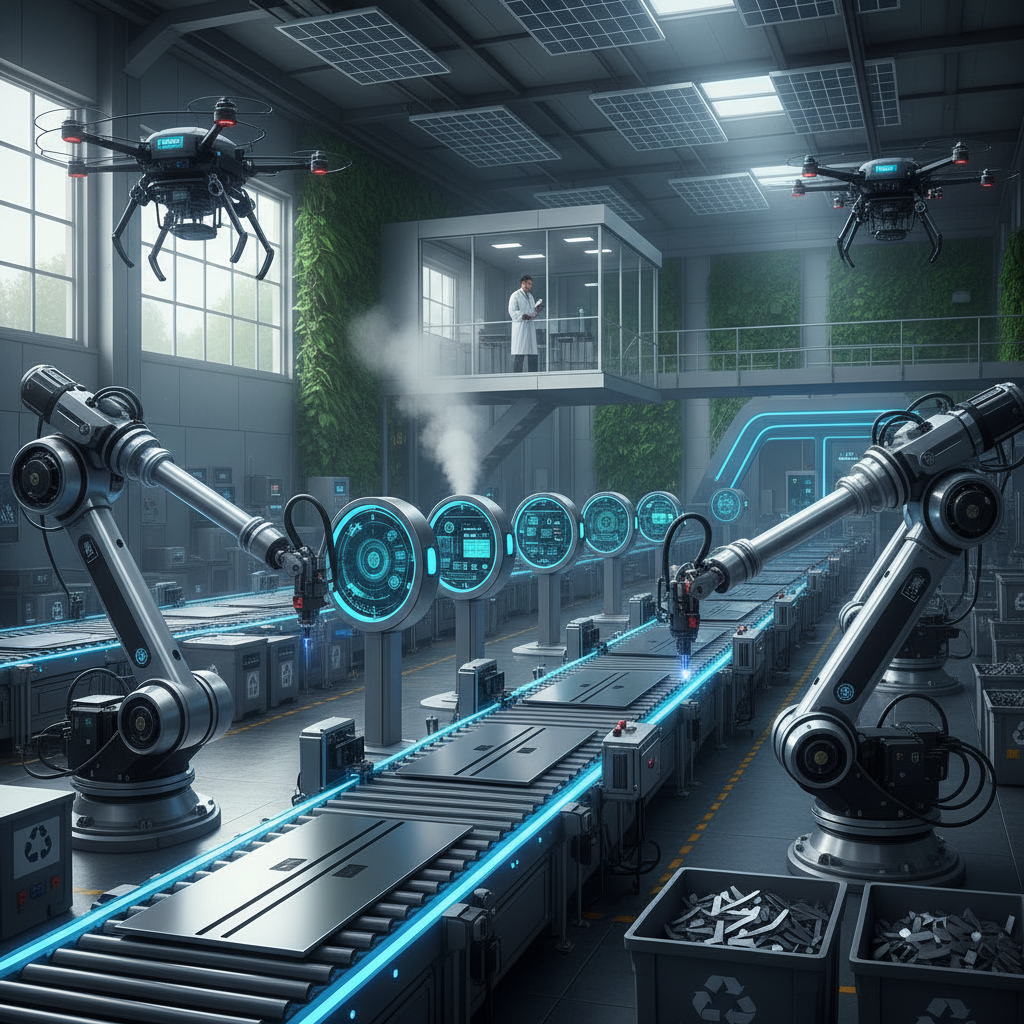

The stainless steel plate manufacturing industry is poised for transformative advancements by 2025, particularly with the emergence of innovative processes that enhance efficiency and sustainability. One of the most notable trends is the adoption of advanced automation and robotics. These technologies streamline production, reduce manual labor, and minimize human error, allowing for higher precision in manufacturing. By integrating machine learning and artificial intelligence, manufacturers can optimize their operations and adapt to varying production demands seamlessly.

Additionally, sustainability is becoming a core focus in the manufacturing processes of stainless steel plates. Innovations such as electric arc furnaces, which use recycled materials as a primary input, are gaining traction. This shift not only lowers the carbon footprint associated with production but also promotes circular economy principles within the industry. Furthermore, the development of eco-friendly surface treatment techniques is on the rise, enabling manufacturers to enhance corrosion resistance while minimizing harmful environmental impacts. These trends reflect a broader commitment to both technological advancement and environmental responsibility in the stainless steel sector.

Stainless steel plates have established themselves as pivotal components across various industries due to their durability, corrosion resistance, and aesthetic appeal. As the global market for stainless steel plates is projected to grow significantly, reaching an estimated $167.48 billion by 2030 with a CAGR of 5.9%, key applications in sectors such as automotive, construction, and food processing are expected to drive this growth. In the automotive industry, stainless steel plates are commonly used in parts that require high strength and resistance to harsh conditions, such as engine hood locking plates and latches, which alone are forecasted to expand from $2.42 billion in 2025 to $3.93 billion by 2034.

Moreover, as the stainless steel industry shifts from focusing on quantity to enhancing quality, manufacturers are prioritizing advanced technology and sustainable practices. This evolution aligns with increasing standards in industries ranging from architecture to medical equipment, where the integrity and longevity of materials are paramount. With ongoing innovations and an expanding application base, stainless steel plates are poised to play an essential role in meeting the demands of the future, catering to diverse markets around the globe.

As we move towards 2025, the stainless steel plate industry is increasingly influenced by sustainability trends. The global shift towards eco-friendly practices in steel production is becoming pronounced, spurred by rising awareness of environmental issues. According to industry reports, sustainability initiatives are projected to dominate the future landscape of steel manufacturing, with an emphasis on reducing carbon emissions and enhancing the recycling of materials. The flat steel market alone is anticipated to reach a size of USD 724.33 billion by 2025, signifying the growing demand for more sustainable products.

In parallel, the sheet metal fabrication services market is expected to contribute significantly to this trend. By 2034, the market size is predicted to expand significantly, driven by applications in essential sectors such as automotive and aerospace. As manufacturers increasingly adopt eco-friendly practices, they focus on utilizing recycled stainless steel and innovative production techniques that minimize waste. This alignment with sustainability not only helps in meeting regulatory requirements but also appeals to a growing segment of environmentally conscious consumers. Hence, stakeholders in the stainless steel plate market must stay informed about these trends to remain competitive and relevant in the evolving landscape.

The stainless steel plates market is poised for significant changes by 2025, driven by evolving demand and supply dynamics. According to a report by Grand View Research, the global stainless steel plates market is expected to reach approximately $30 billion by 2025, growing at a CAGR of 5.1% from 2019 to 2025. This growth is largely fueled by increasing applications in construction, automotive, and manufacturing sectors, which are expected to drive demand for high-performance materials.

On the supply side, fluctuating raw material prices and environmental regulations are critical factors influencing the availability of stainless steel plates. The World Steel Association notes that production costs have surged due to rising nickel prices, which account for over 70% of stainless steel's cost. Additionally, manufacturers are increasingly adopting sustainable practices, leading to new production methods that may alter supply chain dynamics. As companies adapt to both environmental challenges and evolving market needs, the landscape for stainless steel plates will continue to adapt, reflecting the balance of demand and supply complexities in the coming years.

The stainless steel industry is poised for significant evolution in 2025, driven by remarkable technological advancements that enhance the properties of stainless steel plates. Innovations in metallurgical techniques are producing alloys with superior strength and corrosion resistance, enabling manufacturers to meet the increasing demands of various sectors. For instance, the integration of nanotechnology in the production process allows for the development of stainless steel plates that possess improved durability while maintaining lightweight characteristics, making them ideal for applications in aerospace and automotive industries.

Moreover, advancements in surface treatment technologies are revolutionizing how stainless steel plates are utilized. Techniques such as plasma nitriding and laser surface structuring are being employed to create customized surface finishes that enhance wear resistance and aesthetic appeal. These treatments not only extend the lifespan of the materials but also contribute to sustainable manufacturing practices by reducing maintenance needs and material waste. As these technologies continue to advance, they promise to redefine the benchmarks for performance and functionality in stainless steel products, positioning the industry for a dynamic future.